Thanks to our long experience with different subsea construction projects in various parts of the world, even in challenging conditions.

We offer safe, quality-assured, and efficient solutions for subsea construction.

We have the following capabilities related to subsea construction:

- In-house engineering

- Inspection Repair Maintenance technicians

- Divers (surface-supplied diving and saturation diving)

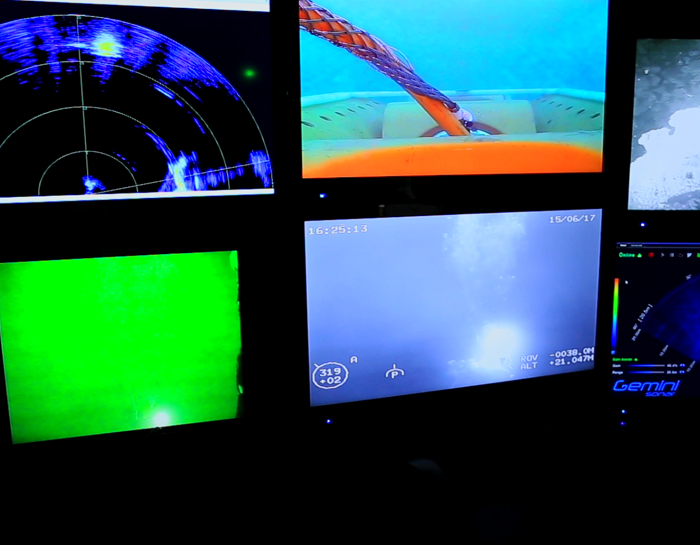

- Various ROVs and technicians

- Multi-purpose daughter craft

- Multi-purpose supply vessel

Capabilities

The plan forms the basis of a successful project and reduces many risks before they occur.

All successful subsea constructions of any asset depend on a detailed understanding of the seabed conditions.

Read about our seabed surveys here.

The high installation costs come partly from the demanding environment in which underwater infrastructure is installed. Streamlining the installation process can cut down on and control costs.

The high cost of installation systems drives the need for efficiency and effective planning.

In addition, it is important to plan details such as which components will be used and where they will be installed, as these will be important in the future and to determine how accessible a system is for future inspection, repair, and maintenance.

Subsea intervention

Subsea interventions are necessary when preparing the seabed for the installation of submarine offshore infrastructure such as cables, pipelines, wind farms, etc. This ensures that the seabed is clean and tidy without any obstacles.

Example: To place a pipeline on the seabed, it should ideally be as flat and regular as possible. However, that is not often the case due to the presence of various geophysical features on the seabed.

We offer jet trenching, mechanical cutting, plowing, airlifting, and offshore geotechnical services. We have certified staff and equipment for surface-supplied diving, saturation diving, and ROV operations.

A reliable seabed intervention’s overall objective is that the surface should be as flat and regular as possible. If it is not flat, pipelines, for example, may need to be installed in a trench or buried in the seabed to prevent the pipeline from being overloaded due to instabilities. According to regulations, pipelines will be buried to protect them from fishing activities or external disturbances once they reach the shoreline. Before installation, we carefully prepare the trenches in the seabed to reduce the risk of span and overstress, ensuring a resilient and safe installation right from the start.

NDE Offshore has experience in carrying out the following underwater installations and can offer the following services:

Cable Installation

NDE Offshore can prepare for and install underwater cables.

Cables are often buried in trenches created to protect them from damage.

Flexible Hoses Installation

Flexible hoses are typically used in applications where a pipe cannot be easily installed, such as in offshore drilling operations and deep-water pipelines. Using hoses greatly reduces the risk of damage to piping and other equipment, which can lead to significant cost savings.

Subsea Infrastructure

It is the critical infrastructure used in gathering, processing, and transporting oil & gas offshore.

SURF

(subsea umbilicals, risers, and flowlines) connect subsea production and surface systems. Umbilicals provide a vital link between the subsea production system, processing system, and the surface and have no contact with the produced fluids.

SPM Installation

A single point mooring (SPM) is a floating buoy anchored offshore that allows liquid cargo handling in areas where a dedicated onshore facility for loading and unloading cargo is not available. They link shore-based facilities and large oil tankers for loading or offloading oil and gas cargo.

Anchor Chain replacement

An anchor chain replacement service provider is essential for any vessel owner, as it ensures the safety and efficiency of the ship’s anchoring system.

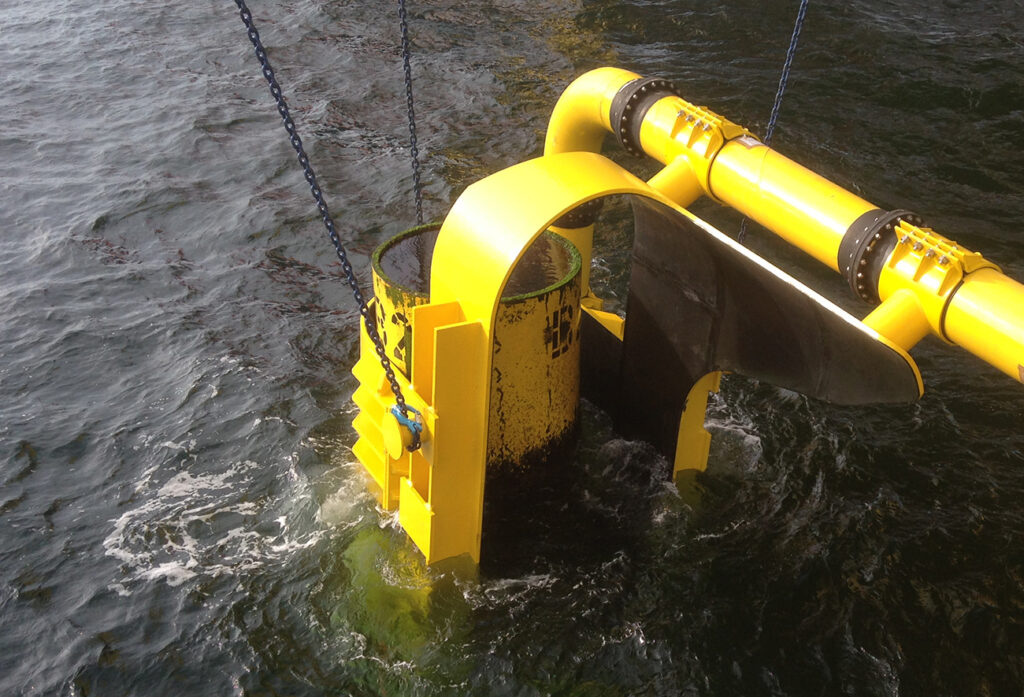

SPM’S & PLEM’S installation

Single point mooring (SPM): A floating buoy/jetty anchored offshore to allow liquid cargo handling such as petroleum products for tanker ships.

Pipeline End Manifold (PLEM):

It is commonly used for subsea manifolds to tie off underwater pipelines.

It is also used to comingle two or more pipelines together and eliminate the

need for additional risers. Refurbishment / Upgrade of existing calm buoy systems.

Refurbishment / Upgrade of existing calm buoy systems

We can help with upgrading existing calm bouy systems.

Asset integrity inspection

Managing an asset’s integrity ensures that all systems and equipment are performing optimally, ensuring operations run continually and smoothly. This also helps extend the life of an investment, further maximizing production and profitability.

Calm buoy terminal services

Our professional and qualified personnel can supply and install CALM buoys and provide a complete maintenance management service for supporting equipment such as floating and subsea hoses. We can also provide and maintain all ancillary equipment, such as hose end valves, spool pieces, and chains.

Inspection & life extension of existing CALM BUOY systems

Our professional and qualified personnel are equipped to provide thorough maintenance management services. Their purview extends beyond the CALM buoys to include supporting equipment such as floating and subsea hoses, encompassing the provision and upkeep of all auxiliary equipment like hose end valves, spool pieces, and chains.

Jet Trenching

Pipelines transporting oil and gas, water and sewerage, and cables for telecommunications and renewable energy are trenched into the seabed, sometimes in coastal shallow water and sometimes offshore in deep water.

Mechanical Cutting

Mechanical cutting, which includes tooling and machining, is a process that uses power-driven equipment to shape and form material into a predetermined design.

Ploughing

- It can be completed in one process.

- Generally good burial

- It can penetrate harder sea beds.

- Economical over longer distances

- Instant cable burial and protection

Air Lifting

Underwater air lift bags are open or enclosed bottom parachute-type designs. These parachute-type underwater lift bags include commercial diving and professional lift bags.

Offshore Geotechnical Services

Geotechnical engineers or engineering geologists perform geotechnical surveys to obtain information on the physical properties of soil earthworks and foundations for proposed structures and repair of distress to earthworks and structures caused by subsurface conditions; this type of investigation is called a site investigation.

Project management:

NDE Offshore also meets the requirements for project management of underwater installations as we have a specialist team of engineers and project managers.

- Construction & project management

- Engineering & procurement

- Consultancy services